Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

The comb/ex on a gas detector is a feature that detects combustible gases and measures their concentration levels. It is an essential component in ensuring safety in environments where combustible gases are present.

Gas detectors are crucial in detecting and monitoring the presence of potentially hazardous gases in various settings, such as industrial plants, construction sites, and laboratories.

The comb/ex feature on a gas detector specifically focuses on detecting combustible gases, which are gases that can ignite or explode when exposed to an ignition source.

This feature helps to ensure a safe working environment by alerting users to the presence of combustible gases and providing accurate measurements of their concentration levels.

By utilizing the comb/ex feature on a gas detector, potential risks can be identified and managed, enabling workers to take appropriate safety measures to prevent accidents and protect lives.

Comb/ex on gas detector is a vital feature that enables quick and accurate detection of combustible gases. An essential tool for safety measures in various industries, comb/ex provides valuable information to prevent potential hazards and ensure a secure work environment.

Comb/ex, short for combustible/explosive, refers to the detection of flammable gases and vapors in the surrounding environment. Gas detectors equipped with comb/ex functionality play a crucial role in ensuring safety in hazardous environments by detecting and alerting users to the presence of potentially explosive or combustible substances.

“Comb/Ex” on a gas detector typically refers to a measurement for combustible gas or explosive atmospheres. It indicates the presence of gases that can potentially lead to combustion or explosions.

The term “Comb” often stands for combustible gases, while “Ex” denotes explosive atmospheres. Gas detectors with these features are crucial for safety in environments where the risk of fire or explosion is a concern.

Gas detectors with comb/ex capabilities are specifically designed to monitor the concentration of flammable gases and vapors in the atmosphere. The primary purpose of this feature is to prevent accidents by providing early warning signs and allowing individuals to take necessary precautions.

By continuously monitoring the air, comb/ex gas detectors help to minimize the risk of explosions or fires in potentially hazardous environments.

The importance of comb/ex gas detectors cannot be overstated when it comes to ensuring safety in hazardous environments. These detectors play a critical role in protecting both individuals and the surrounding environment.

Here are some key reasons why comb/ex is so crucial in such settings:

Comb/ex gas detectors are indispensable tools for identifying, monitoring, and preventing incidents from involving flammable substances. Their ability to issue timely alerts and enhance safety measures significantly contributes to maintaining a secure environment in hazardous settings.

By detecting invisible threats and acting as an early warning system, comb/ex gas detectors provide invaluable protection to individuals working or living in such environments.

Comb/ex on gas detectors is a valuable feature that allows for quick, accurate measurements of combustible gas levels. This technology offers a safer and more efficient way to detect gas leaks and maintain workplace safety.

Comb/ex technology is an essential component of gas detectors used in various industries to ensure safety in hazardous environments. This innovative technology combines two different detection methods, catalytic combustion (comb) and infrared (ex), to provide accurate and reliable gas detection capabilities.

By incorporating these two methods, comb/ex detectors can efficiently detect both combustible gases and hazardous substances in the air.

Comb/ex gas detectors consist of several key components that work together to ensure effective gas detection. These components include:

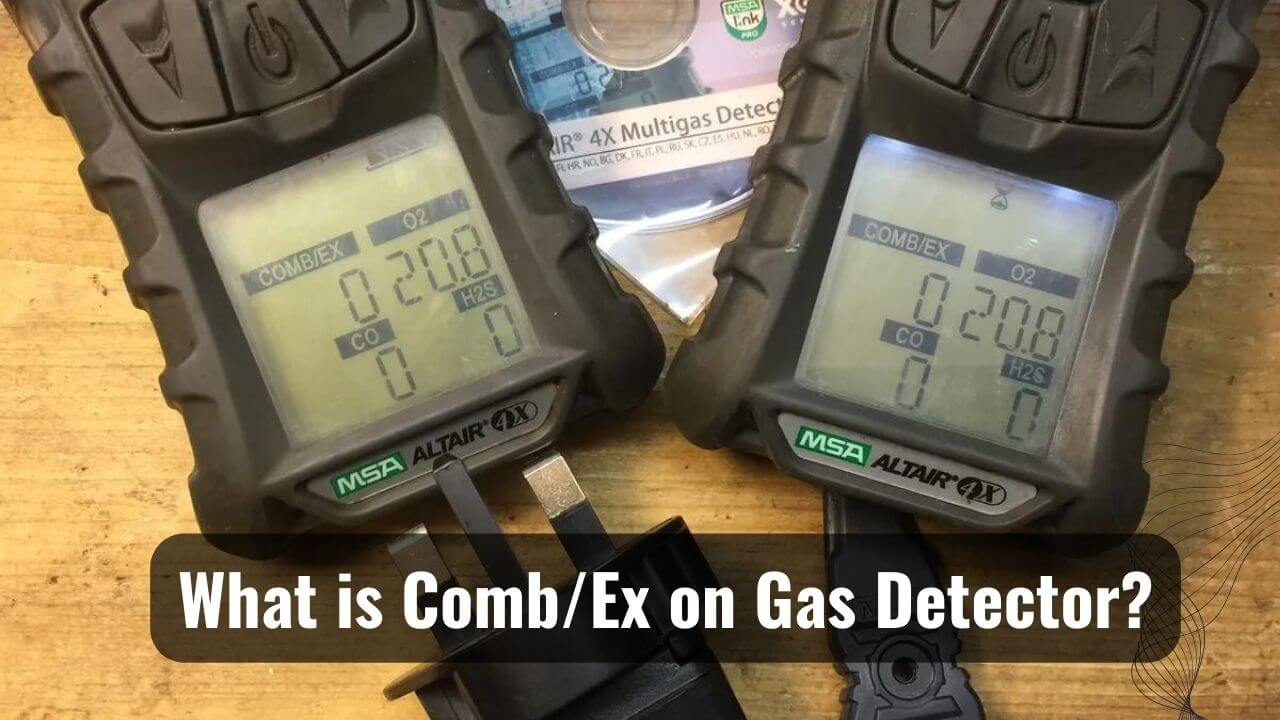

The term “msa altair 4x comb/ex” refers to the MSA Altair 4X, a multi-gas detector commonly used for monitoring and detecting the presence of various gases in the environment.

The “comb/ex” likely indicates that it is capable of detecting combustible gases and has an extended range of capabilities. It’s a versatile tool used in industrial settings, firefighting, and other environments where gas detection is crucial.

A comb/ex on gas detector works by using sensors that detect the presence of combustible gases. These sensors can be based on different technologies such as catalytic, infrared, or electrochemical.

When the sensor detects the gas, it sends a signal to the detector which triggers an alarm or warning to alert the user of the potential danger.

Using a comb/ex on gas detector offers several benefits, including early detection of combustible gases, prevention of explosions or fires, protection of workers’ safety, compliance with safety regulations, and reduction of potential damage to property and equipment.

Generally, calibration should be done at least once every six months to ensure accurate readings and optimal performance. Regular maintenance and sensor checks are also important.

To sum up, the comb/ex gas detector is an essential tool for ensuring safety in potentially hazardous environments.

Its ability to detect and analyze gas levels accurately is crucial for preventing explosions and other dangerous incidents. The device’s reliable functionality and user-friendly features make it a valuable asset in various industries, including oil and gas, chemical, and manufacturing.

With its innovative technology and robust design, the comb/ex gas detector provides greater peace of mind to workers and employers alike. By continuously monitoring and alerting users to changes in gas concentration, it enables prompt action and mitigates potential risks.

Investing in a high-quality gas detector like the comb/ex is an investment in the well-being of both employees and the overall workplace environment.

So, prioritize safety and equip your workplace with the comb/ex gas detector to ensure a secure and protected work environment.